My tryst with acoustic panels

Things

you need (for 7 Panels)

1.

Ply

wood – 12 mm – 6 ft X 4 ft = Rs. 900.00

2.

Labor

charges to cut them into 3 inches slabs = Rs. 300.00

3.

Metal

“L” clamps to make frame = 2” X 2” - 56 nos @ Rs. 5 each = Rs. 310.00

4.

Screws

– “4 X 20” – CSK - 224 nos = Rs 200.00

5.

Fabric

– behind the panels – 9 Meters @ Rs 40 per meter = Rs. 360.00

6.

Fabric - Front panel – 11 meters @ Rs 100 per meter

= Rs. 1100.00

7.

Small

metal L clamps to make hanger = 14 nos @ Rs 5 each = Rs. 60.00

8.

Misc.

nails and screws = Rs. 100.00

9.

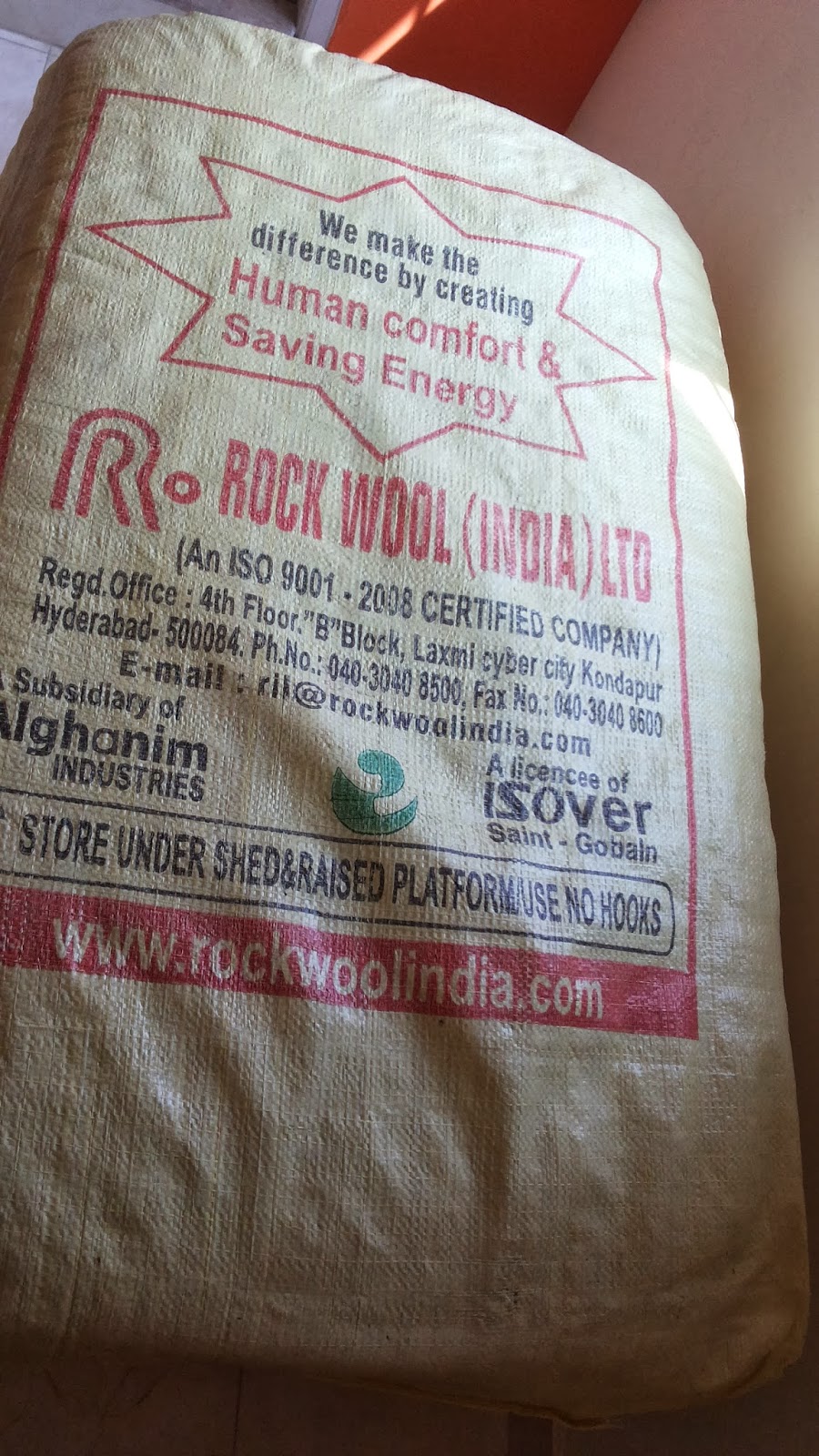

Rock

wool = 50mm thick – 64 Kg density = Rs. 2000.00 (inclusive of Rs. 500 –

transportation)

Tools

that you need

1.

Screw

driver

2.

Drill

with the right sized bits

3.

Hammer

5.

Measuring

tape

6.

Pencil

7.

Safety

equipment – pair of gloves and breathing mask

8.

Don’t

remember, what else – but use your imagination J

And so

the mitigation of this ‘untreated’ to “TREATED” J (sounds nice doesn't it). (At least some treatment)

And so I

bagan in keeping with the wisdom of the “gurus”, to make some acoustic panels

for my home studio.

After

much searching, found one guy would sell one bag of Rock wool slabs and ship it

also… and boy was I glad and so …..

First

things first, why seven panels? The Rock wool slabs come in a bag of 14 and I figured

that, since they are quite thin, double it and viola the magic number 7.

Home

work- I looked at the videos and information in the web and they all talk about

making panels out of wood (not ply wood) and getting wood (decent quality)

cheap and at the sizes you want can be a daunting task when home depot is not

accessible. And so I had this brilliant idea of using plywood instead of wood

(it is going to be light and easily accessible and mostly cheap).

After

buying the plywood, I got it cut from the shop itself and then I thought, how

hard could it be, let me just nail the darn thing and boy was I shocked. The

wood just split when I tried to make a frame….

After

buying the plywood, I got it cut from the shop itself and then I thought, how

hard could it be, let me just nail the darn thing and boy was I shocked. The

wood just split when I tried to make a frame….

Back to drawing

board… (just a phrase)

Then it

struck me, what better way to do this, then with some “L” clamps and screws. And

that is what I did.

So I began

measuring the “L”clamps against each slab of wood, marked it for holes that

need to be drilled. Then drilled the holes and mounted one end of the “L” clamp

on all the small sized slabs (23” – This is based on the size of the rook wool).

So I began

measuring the “L”clamps against each slab of wood, marked it for holes that

need to be drilled. Then drilled the holes and mounted one end of the “L” clamp

on all the small sized slabs (23” – This is based on the size of the rook wool).

Now I

needed to nail the back fabric to the frames and chop the extra off.

Once this

was done, I turned the frame over with the fabric at the bottom and filled it

with two slabs of rock wool. Gave it a tight squeeze.

Now it

was ready for the main fabric to be mounted.

It is

very important that this is done carefully (and hence changing tone from I to

you J)

.

·

Lay

the fabric on the floor (evenly and clean)

·

Place

the frame with the rock wool in such a way that the backing fabric is on top.

·

Make

sure that there is enough fabric all around to help roll it over the frame.

·

Now

stretch the fabric starting from one end of the smaller size and start nailing

them to the frame from the center.

·

Now

repeat the process of the longer side.

·

Measure

and mount the small “L” clams to the frame to be used for hanging the panel.

Once

this is done, all that is needed to finish, is finish the edges… (this is easier

said than done)

·

You

would need to cut the excess pieces of fabric and then tuck one end and fold

the other end to give it that professional look. Now nail the fabric on to the

frame.

·

You

are DONE.

Comments